What is Metal Deck?

Building construction requires materials which in addition to being durable, also save on costs and time of construction. One of the most important and practical materials used in building construction is the Metal Deck.

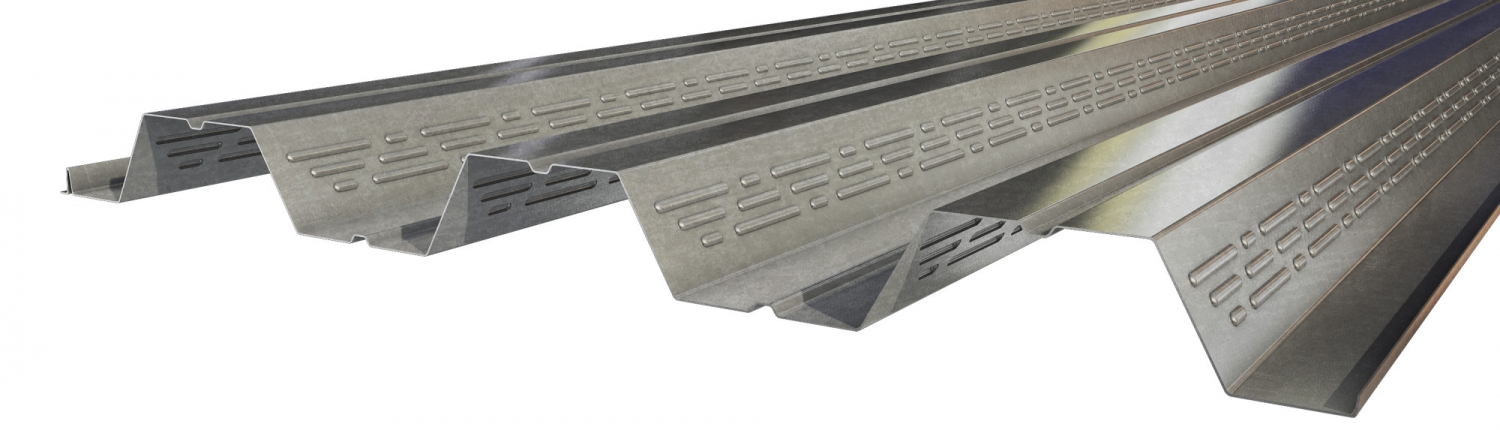

Steel deck sheet is produced with pitch 65 and pitch 75 and the name of this product is also called Metal Deck. Metal deck is a steel structure that is used for the implementation and installation of building roofs, which along with various treads in the form of a circular oval, is of course a taste, and is originally from the family of trapezoidal formations.

This product is produced from steel sheet with a width of 1 to 1.5 m. by cold-rolled forming method and is mostly used in the construction of roofs, which is called Steel deck roofs.

Metal Deck Sheet

Steel deck is a structure consisting of corrugated steel sheets that is used to build the roof and floor of a building. Metal deck roof is a type of composite roof that is made using galvanized corrugated steel sheets and reinforced concrete.

The design and construction of steel deck is such that it is used for high strength. These steel products are made in a way that maximizes the properties of steel. One of the most important advantages of this deck is that it reduces the cost of transportation and installation to a minimum, and the very long life of this structure is one of the advantages of this structure. The one-handed and cohesive structure of these locking structures also gives an attractive appearance.

Due to its simple implementation, high implementation speed, relatively low cost and good safety, this deck is widely used in the construction of various structures.

Metal Roof Deck

Metal Roof Deck is one of the new products in the construction industry that is used to build roof. This product has less weigh than old ceilings and can be implement quickly. This building product, which is made of galvanized sheets, is very useful for the roof because its metal is very resistant to corrosion and humidity and increases the life of the structure.

Components of Metal Roof Deck

This product due to withstand a lot of load and at the same time has good flexibility, consists of four semi-heavy components: galvanized sheet (coverage sheet), cutter (shear stud), reinforcement (ribbed rebar) and concrete that is heavy, which we will introduce them in the following.

*Galvanized Sheet: Galvanized sheet is a type of steel sheet which is coated by zinc and so-called galvanized. Galvanizing or galvanization causes a strong coating to be applied to the steel sheet, preventing the steel from reacting with the air oxide, leading to rust and corrosion of the metal. The galvanized sheets used for this purpose have a wavy or shutter shape and for this reason they are also called colored shutter sheets or sinusoidal shutter sheets.

*Shear Stud: One of the main part of metal roof deck is Shear Stud which is used to connect the galvanized sheet to the concrete. To do this, a welding machine is used to fit firmly in the concrete. The maximum diameter of this element is 20 mm. and its height varies depending on the sheet used, the minimum height after placing in concrete is 40 mm.

*Armature: Armature or ribbed rebar is a steel rod that has protrusions called a “Tread”. The presence of treads in this product makes better adhesion to concrete. Concrete may crack due to high pressure, but ribbed rebar with high tensile strength prevents from concrete cracking and is therefore used in the construction of steel deck roof.

*Concrete: Concrete is one of the most widely used construction and industrial materials, which is composed of materials such as cement, sand aggregates and water. Concrete obtained by mixing water with cement and aggregate hardens after drying and changes to a very strong material used in steel deck roof.

Application of Metal Deck

Now that we are familiar with the metal deck and its components, it is better to get familiar with its application as well. Due to its excellent features such as quick installation and light weight compared to old and traditional roofs, this product is not only used in roof construction and is also used for items such as half floor and construction flooring.

This product can also be used to build building canopies, because it creates shadow and protects building from rain, sunlight and excessive heat.

Another important application of metal deck that is not yet common in Iran is the construction of structural doors that store recycling and waste. These places have two doors like the one pictured below that open from the side and are very durable because trucks and garbage trucks and recycled materials may collide and be damaged.

Advantages of Metal Deck

As mentioned before, this product has a lot of resistance. But metal deck has other unique advantages that have found many buyers:

*Light Weight: Today, the construction of structures with light weight is very significant. Roofs made of steel deck weigh less than traditional roofs. This advantage is more visible in multi-floor and high-rise buildings. The higher the height of the structure, the greater its weight, and therefore the use of metal deck, helps to significantly reduce the weight of the structure.

* Affordable: Using this product in the building is very cost-effective because in addition to labor and transportation costs, the amount of concrete consumption of the whole structure is also saved, also the usage of rebar is reduced. Thus, it can be said that it reduces the additional costs of the construction project.

* Easy Installation: To install this product no need a crane or heavy equipment and it can be easily installed by hand. This method not only speeds up the construction of the building but also reduces the cost of purchasing or renting additional equipment.

* Increase the Safety of Workers: There is no empty space between the armature in design of the metal deck like other roofs. If workers’ feet get stuck between the armatures, there is a high probability of an accident. It also acts as a platform to build the next floor of the building by installing this product.

* Maintenance and Repair with Less Cost: Because this product is produced by galvanized sheet, it does not corrode or rust if water penetrates the concrete and lasts for years, thus the cost of building repairs will be decreased.

*Permanent Molding: Another advantage of using a metal deck is that it acts as a permanent molding. Instead of using a temporary concrete molding, a metal deck is used inside the structure, which is both a mold ready for concreting and improves the yield strength of the structure.

Different Types of Metal Deck Sheet

Generally metal deck sheets can be divided into two categories: roof deck and floor deck. Many years ago for the first time, galvanized sheet was used for the roof of the building only as a mold on which reinforced concrete was poured, and their performance function was only to carry during the operation and before setting the concrete, and to save costs. In the term of this group of roof sheets are called Proof Deck.

Over the time, the production mechanism and also the implementation of these roofs changed so that a mechanical conflict occurred between the lower sheet and the reinforced concrete of the roof and with the help of cutters and molds around the concrete slab, the roof was connected to the joists. In such a situation, the sheets became the roof tensile reinforcement, which together formed the conventional steel deck roof, and the sheet used in this set became known as the Metal Deck. This sheet is now considered a structural element in the roof and presents the several advantages as mentioned earlier.

The Last Word

Metal deck is a component of building that is produced by galvanized sheet and concrete. This product has excellent advantages such as light weight, easy portability and fast installation. The sheet with thickness 0.4 mm. to 0.8 mm. is used to produce this product.

Sarir Sanat Amir Company is a manufacturer of various types of Metal Decks in different thicknesses and dimensions. If you have any questions about this product, you can contact the experts of Sarir Sanat Amir.