Z-Purlin

One of the most widely used products in the construction of various types of sheds, steel and metal structures, train rails and etc. is Z purlin (Z Profile) which is supplied in different sizes, so has a lot demands.

Literally, a profile means a fixed section that has a certain length. The shape of the profiles is usually rectangular or square and they are manufactured in small and large dimensions. Profiles or purlins are very economical and are widely used in industrial, construction and civil engineering projects, automotive, shipbuilding, etc.

Z Purlin has some interesting features such as being cost-effective, makes balances and strengthens of the structure. That is why industrial activists and manufacturers pay special attention to this product. The profile is divided into two categories, open and closed, and the z-profile is placed in the open category.

What is an Open Purlin (Profile)?

Open purlins (profiles) are steel products that have an open cross-section and a fixed length and are cut by cold rolling. Due to cold –rolled method, these profiles have precise dimensions. Also their surface is smooth. These profiles are made of hot-rolled and galvanized coil, which have stainless steel properties and have the following unique features:

• High welding and screwing capability

• Fire proof

• High bearing weight capability

• Easy installation

• High color-ability

• Good cutting ability

Different Types of Open Purlins

Open purlins are divided into 8 main categories based on their shape and shear section:

1. Beam

2. Z-Purlin

3. Framework Purlins

4. Gutter Purlin

5. Window and Door Frame

6. Equal Angle

7. Beam Profile

8. Steel Strap and Flat Bar

What is Z purlin?

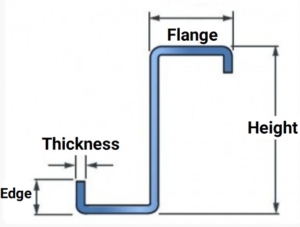

This purlin is in the shape of the English letter Z. This purlin consists of three parts: flange, height and edge. The standard height of this product is 18 cm., but it can be manufactured up to 45 cm., which depends on the cutting roll.

The flange or width of this product is Max.6 cm., its thickness is 2 mm., 2.5 mm. and 3 mm and its edge is 1.5 to 2 cm. The standard length of this product is Max.12 m., but due to the good cutting ability of this product, it can be cut to any length according to the customer’s order.

Z-Purlin Manufacturing Method

This product is manufactured by two methods: Press-breaking and roll-forming. In press-breaking method, which is done by the machine, first the sheet is passed through a punch and mold and produced to the desired size and shape. In this method, the Z Purlin is formed by pressure and has a large error, so the roll-forming method which is more accurate is used. In the roll-forming method which is performed in cutting workshops, first the roll of galvanized sheet or ho-rolled sheet passes through the decoiler (roll opener) and becomes a sheet. Then, the sheet goes through different rollers. As the sheet passes through these rollers, both the sheet becomes flat and Z-shaped. In this case, the Z Purlin is produced either simple or punched. If the customer needs it, there is a spinning machine at the first of the production line that punches the purlin and then cuts with a guillotine based on the customer’s desired length. Finally, it is guided by an accelerator to a table called a Loading Table and is ready to be packed. The most common application of this product is in the construction of sheds and gym or sports salons roofs. However, this product is not only used in shed roofs and can be used in other industries and projects such as:

-Rail Construction: The material of the rail must not only be able to withstand a lot of weight, but also have anti-corrosion and anti-impact features, and for this reason, Z Purlin is used in the rail construction.

-Solar Panel: A solar panel is a device that captures solar energy and converts it into electricity. The Z Purlin is used to tighten the solar panel to the bases of the solar panels.

-Steel Frame Construction: One of the most widely used items of this product is steel frame construction. The steel frame consists of vertical and horizontal columns that are connected to each other by welding or bolts. This product is used together with other open profiles such as beams to build very large structures such as garages, warehouses, workshops and factories.

– Plumbing Support Construction: Oil and gas pipelines need a strong support because they cross natural unfavorable routes. Z Purlin does this well and is a strength element for structure.

-Multi-Floor Buildings Reinforcement: The building with more floors has the more pressure and load on the main columns rather than building with less floor. In addition to power transmission, this product is used as an additional member to withstand the load of multi-floor buildings. It also increases the building’s earthquake resistance to some extent.

– Composite Sections Structure: Today, due to many developments in civil sciences, the composite sections construction has become common. Composite sections are a combination of concrete and columns that have very high strength. Z Purlin is also used in manufacturing of these sections.

Advantages of Z-Purlin

– Production Possibility Based on Customer’s Order: One of the most important advantage of this product is the possibility of cutting and producing it based on the dimensions provided by the customer. This product can be molded by cold-roll forming method and produced in various dimensions. Therefore, most buyers are looking for a manufacturer who can make the dimensions according to the needs of their project. Produce roll forming method. Sarir Sanat Amir Company for the first time in Iran and as the first factory, can produce Z purlin from 120 mm. to 450 mm. height by roll forming method according to the customers’ request.

-Affordable: The use of this purlin is economical affordable because in large projects such as the construction of a sport salon or shed, they are easier to transport and carry than beams and can be loaded in higher tonnage.

-Special and Unique Design: The shape of steel products in structures is also very important. The unique design of this Z Purlin also makes the facade of the building beautiful. Also, the cross section of this product is such that it distributes the load on the structure well and does not concentrate the pressure in one place only.

-Light Wight: The light weight of this purlin is impressive. Compared to other open purlins such as beams, which are very heavy, this product is light weight and thus reduces the overall weight of the steel frame.

Factors Affecting on Z-Purlin Selection

– Project Under Implementation: There are important factors in choosing a purlin (profile). One of these factors is the type of project. It may be a large project and will require a lot of building materials such as sheds. That’s why project contractors use products that are both lightweight and reasonably priced. For this reason, most construction project managers come to this product.

-Product Material: The Z Purlin selection also depends on its material. This product is made of hot-rolled coil with St37 quality, which is made of semi-mild steel and is used for lighter structures. For heavy applications such as petrochemicals and cranes, hot-rolled sheet with quality St52 is used, which has more strength.

-Product Brand: Another factor that influences the selection of this product is its brand. Buyers before taking any action, they pay attention to the brand. There are few factories and companies in Iran that manufacture this product, one of them is Sarir Sanat Amir Company. This company is the only workshop in Iran that produces this product by cold-roll forming method based on Iranian and foreign standards in the dimensions required by the customer.

Factors Affecting on Z-Purlin Purchase

The purchase of Z Purlin depends on various factors such as market fluctuations, the price that offered by the seller, as well as the shipping and handling conditions of the product. If the market fluctuates be too much, then purchase Z Purlin will be affected.

Also, the manufacturing method of this product affects the purchase of this product. Purlin and profile buyers are often looking for products that are of good quality. As mentioned before, the manufactured Z Purlin by the roll-forming method, in addition to quality, has more precise dimensions and therefore attracts the attention of buyers.

Factors Affecting on Z-Purlin Price

Steel products is one of the largest active industries in the country, which connects a chain of important businesses such as building construction, mining, freight and trade. Therefore, with increasing prices of goods and the supply and demand of each industry involved in ironware, the price of this product also changes. Factors affecting the price of this product include the following:

• Currency Price Fluctuations: The steel industry is an area that is highly dependent on exports and imports. Negative and positive signals which sent from various currencies, especially the dollar $, to the steel market are one of the main factors affecting the price of Z-Purlin.

• Hot-Rolled Coil Price: Hot-rolled coil which is the raw material of hot-rolled profile, has a great impact on the price of Z Purlin. Because the hot-rolled coil is the main material of various industries such as automotive, construction, petrochemical, aerospace and even home appliances, changes the price of this product, not only changes the price of Z Purlin, but also affects other industries.

• Iron ore Price: Iron ore is the raw material of most steel products, especially Z Purlin, which is extracted from iron ore. Simultaneously with increasing prices of iron ore, the price of steel products will be increased.

• Freight Cost: Domestic and international shipping costs vary depending on shipping time, fuel cost and economic conditions. For example, one day in the country, the cost of fuel may suddenly increase, which in turn increases the cost of transportation, and hence the price of purlin also increases to some extent. Note that the cost of fuel is not limited to trucks and trailers that are gasoline, but also includes ship fuel.

• Global Inflation: Global inflation has a significant impact on the price of Z Purlin. Unwanted events such as the corona, which has gripped the world in recent years, have severely affected the global market economy, with rising steel prices and inflation. Hence, global inflation has always affected the price of this product.

• Amount of Supply and Demand: Supply and demand are the two main issues in the economy of each country. There is a basic rule in supplying and demanding that says with more demand and less supply for a good, the price will be increased. This is especially true in the steel market. The rarer the profile in the market, the higher the price.

• Wight of Purlin: Z purlin is a semi-heavy open section that with increasing the thickness the weight also will be increased. For example, purlin Z with a thickness of 3 mm. has weight of 44 kg., but Z purlin with a thickness of 2 mm. has weight of 30 kg. Of course, this amount of weight is with tolerance and may be different on the scales.

• Slab Price: Slab, which is one of the raw materials for steel coil and Z purlin, affect the price of Z purlin. Slab is an intermediate product of some steel mills and used to produce steel coils such as hot-rolled and galvanized coil. So, no matter how much the price of this material changes, the price of Z purlin will also change.

Material of Z Purlin

Z Purlin is made of hot-rolled coil which is manufactured according to Iranian and international standards. The applied quality of hot-rolled coil in making this product is St37 and St52, which have different chemical compositions.

Standard of Z Purlin

This product is manufactured according to the German standard DIN 17100 (RSt37-2) and the European standard EN 10025 (S235JR). The S235JR stands for European standard shows the grade of its steel. This grade is a steel that is made for construction purposes and has a good cutting. This steel has a high welding capability and is therefore used to produce Z purlin. The minimum yield strength of this steel for purlin is 165 MPa, which indicates the amount of plastic deformation in a steel piece.

The Last Word

Z purlin is one of the most widely used products in the construction of various structures such as roofs of sheds and gyms, train rails, solar panels, steel structures, piping support and composite sections. As mentioned, this product is obtained from hot-rolled coil with St37 and St52 qualities, its height is from 12 to 45 cm., which is manufactured with thicknesses of 2 mm., 2.5 mm. and 3 mm.

Sarir Sanat Amir Company is a manufacturer of standard Z purlin in the country, which produces this product in different sizes by using cold-roll forming machines and an advanced production line. Contact our experts for free Consulting on your projects as well as price inquiries.